Introduction of 4043 & 4047 Aluminum Welding WireIn GB/T10858-2008 aluminum and aluminum alloy standards, 4 series of aluminum welding wires include: 4009, 4010, 4011, 4018, 4043, 4043A, 4046, 4047, 4047A, 4145, 4643....

Introduction of 4043 & 4047 Aluminum Welding Wire

In GB/T10858-2008 aluminum and aluminum alloy standards, 4 series of aluminum welding wires include: 4009, 4010, 4011, 4018, 4043, 4043A, 4046, 4047, 4047A, 4145, 4643.

Aluminum silicon (4XXX series), silicon lowers the melting point of aluminum and improves flowability. Its main use is as a filler metal. Series 4 has good weldability and is considered a non-heat treatable alloy.

The difference between 4043 & 4047 Aluminum Welding Wire

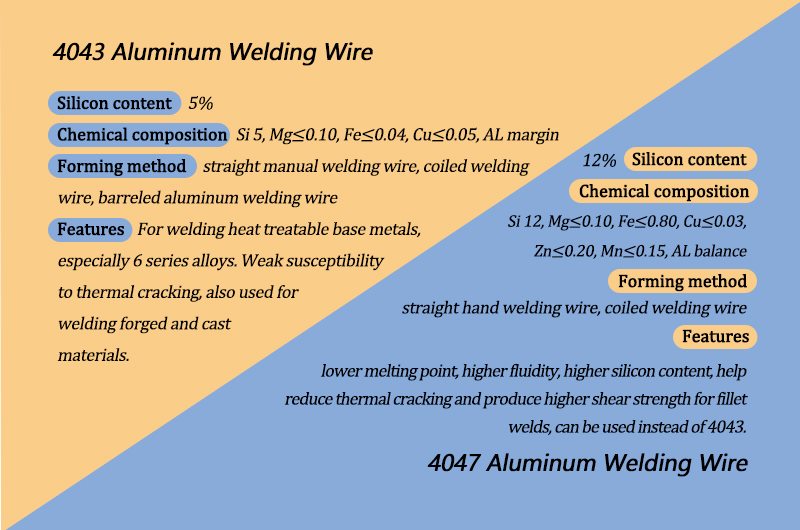

Aluminum silicon alloy welding wire 4043

Features: This product is an alloy welding wire containing 5% silicon, suitable for welding cast aluminum alloys

Typical chemical composition: Si 5, Mg≤0.10, Fe≤0.04, Cu≤0.05, AL margin

Uses: ships, locomotives, chemicals, food, sports equipment, moulds, furniture, containers, containers

Aluminum silicon alloy welding wire 4047

Features: This product is an alloy welding wire containing 12% silicon, suitable for welding various casting and extrusion aluminum alloys. low melting point and good

The fluidity of the base metal makes the welding deformation of the base metal very small.

Typical chemical composition: Si 12, Mg≤0.10, Fe≤0.80, Cu≤0.03, Zn≤0.20, Mn≤0.15, AL balance

Uses: welding or surfacing light alloy processing industry.

Features of 4043 & 4047 Aluminum Welding Wire

4043 silicon alloy aluminum wire, 5% silicon content. For welding heat treatable base metals, especially 6XXX series alloys. Because of its weak sensitivity to thermal cracking, it can also be used to weld forged and cast materials, and silicon enhances the flow of concrete, so it is highly praised by welders.

4043 aluminum-silicon welding wire is used for argon arc welding, and can be precisely wound into a coiled wire with a minimum diameter of 0.8mm. The diameter is from 1.6 to 6.0mm for manual argon arc welding wire, and it can also be used as barreled aluminum welding wire (diameter 1.2/1.6mm) for aluminum welding robots.

4047 low temperature aluminum welding wire: 12% silicon content, aluminum silicon welding wire designed for brazing, with lower melting point and higher fluidity than SAL4043, can also be used as welding material, can be used instead of 4043, with higher silicon content, has Helps reduce thermal cracking and produce higher fillet weld shear.

4047 is brazing (oxygen welding), which needs to be welded with 201 aluminum brazing powder. It can also be used for argon arc welding under certain circumstances. Manual welding diameter 1.6~6.0mm.