4047 aluminum solder is an aluminum-silicon solder, which is one of the most widely used materials for brazing aluminum alloy materials. Common aluminum-silicon alloy welding materials include welding rod, coil wire and welding ring, which are respectively called: aluminum-silicon welding rod, aluminum-silicon welding wire, and aluminum-silicon welding ring....

Introduction of 4047 Aluminum alloy brazing rod

4047 aluminum solder is an aluminum-silicon solder, which is one of the most widely used materials for brazing aluminum alloy materials. Common aluminum-silicon alloy welding materials include welding rod, coil wire and welding ring, which are respectively called: aluminum-silicon welding rod, aluminum-silicon welding wire, and aluminum-silicon welding ring.

Chemical composition of 4047 Aluminum alloy brazing rod:

|

Chemical components |

Si |

Zn |

Fe |

Cu |

Mn |

Mg |

Al |

|

Technical requirement |

12±1% |

<0.2 |

<0.8 |

<0.3 |

<0.15 |

<0.1 |

Margin |

*Technical requirements for chemical composition comply with American Welding Society standard AWS A5.8/A5.8M: 2004 BAlSi-4.

Brazing process of 4047 Aluminum alloy brazing rod

4047 this aluminum-silicon soldering material is used to weld aluminum with 201 aluminum powder welding. It is a kind of brazing. It is suitable for welding aluminum with relatively high purity. The working melting point temperature is between 580-620 degrees, so It is suitable for people with certain welding experience to weld thin aluminum. Similar welding materials with a lower melting point, such as low-temperature aluminum electrode WE53 solid, have a low melting point during welding, but it is about 200 degrees lower than the melting point of 4047, making low temperature aluminum welding easier.

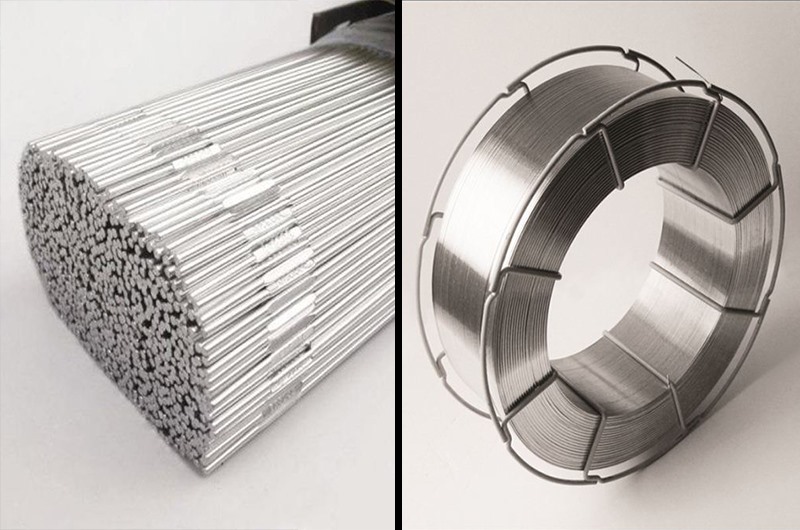

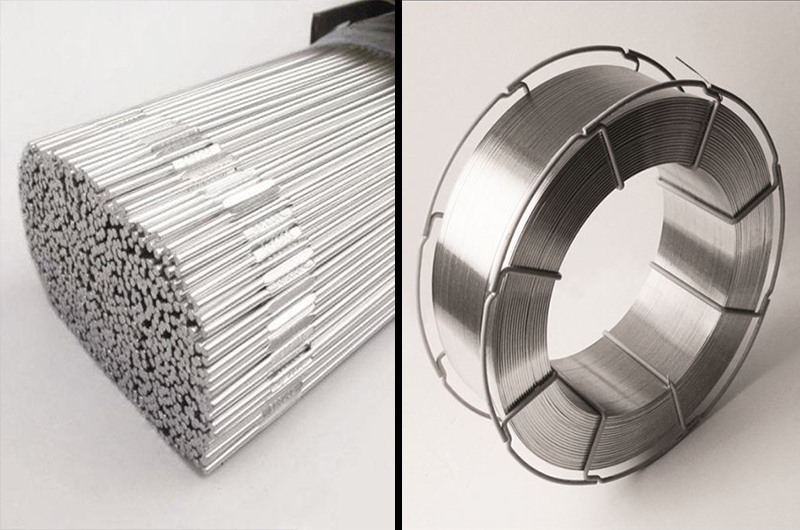

Specifications of 4047 Aluminum alloy brazing rod

Rod diameter: 1.2, 1.6, 2.0, 2.4, 3.0, 3.2, 4.0, 5.0 (mm)

Rod reel size: D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg)

Packaging: coiled wire, straight wire, coiled wire, barrel

Rod characteristics: 12% silicon content, good fluidity, low welding temperature.

Recommended welding method: brazing (commonly known as: oxygen welding, flame welding), with 201 aluminum powder.

Application of 4047 Aluminum alloy brazing rod

This product is suitable for flame brazing and induction of aluminum heat exchangers for refrigeration and air conditioning, aluminum heat exchangers for refrigerators and freezers, heat exchangers for automobile air conditioners, aluminum heat exchangers for heat pumps, aluminum rows for cold storage, various aluminum pipes, and aluminum connecting parts. Brazing, furnace brazing, etc.