The effect of annealing process of 4043 aluminum plate cast-rolled billet on the cast-rolling process. During the solidification of aluminum alloy cast-rolled billet, the motion state of metal atoms is changed to an orderly arrangement....

The effect of annealing process of 4043 aluminum plate cast-rolled billet on the cast-rolling process. During the solidification of aluminum alloy cast-rolled billet, the motion state of metal atoms is changed to an orderly arrangement. The aluminum atoms form crystals according to the position of the face-centered cubic lattice, alloy elements and According to its crystal structure, atomic size and chemical affinity, impurities form interstitial solid solutions, replacement solid solutions or intermetallic compounds in aluminum. Segregation and dendrite structure will occur in this process, which is unique when the liquid phase is transformed into a solid phase. The nature and solid phase cooling is too fast because the diffusion of the elements cannot proceed sufficiently. In addition, the heritability of the cast-rolled billet structure also has an impact on the quality of the 4343 aluminum plate, which is of great significance to the study of the properties of the 4343 aluminum plate. Homogenization annealing can not only ensure that dendrite segregation does not occur again, so that the solute concentration tends to be uniform, and improve the uniformity of the structure, but also can prevent the generation of internal stress, help to enhance the plasticity of the ingot, improve the process performance, and effectively Avoid cracking during billeting.

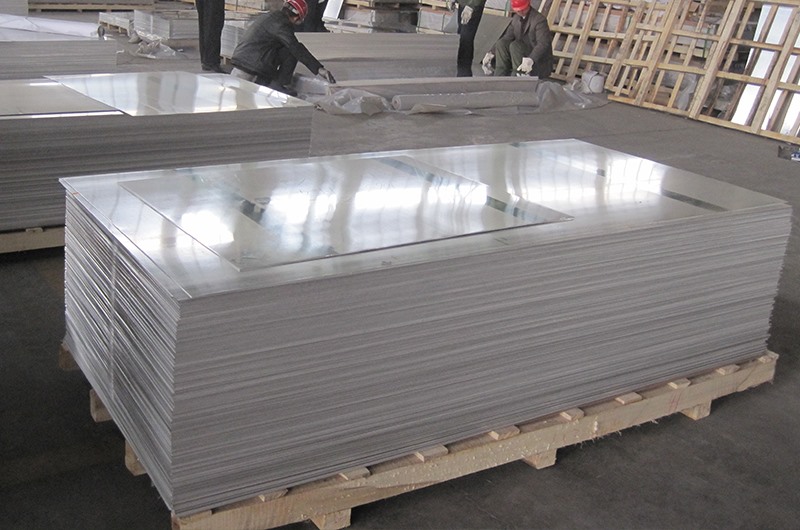

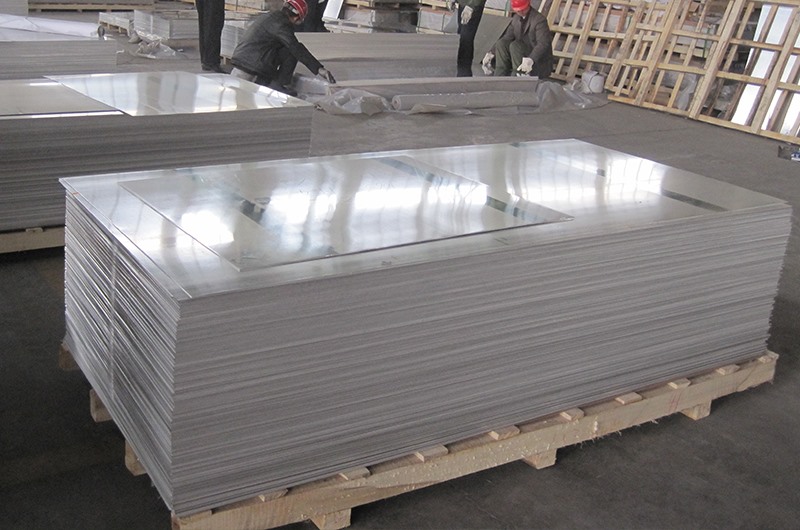

2 4343 Aluminum plate cast-rolled billet before and after annealing, the microstructure and morphology of the impact on the rolling performance. In the process of casting and rolling, the cast roll sleeve is used to transfer the melt heat generated in the cast-rolling zone to the cooling water in the roll core, and the rest Take away by the strip blank. The crystal grows in the direction of heat conduction and points to the inside of the melt, and the melt on the surface will be chilled. Since the melt in the middle layer has not been chilled, the solidification rate is slow. In the cast-rolled slab, even the upper, middle, and lower sides of the same plate surface have different structures, and there are more serious segregation phenomena and more dendritic structures in the middle of the plate surface. This is because during the casting and rolling process, there is a temperature difference on the same plate surface, and the cooling intensity received is different. The homogenization annealing study on the intermediate semi-finished product with a thickness of 5.5 mm shows that annealing at 520 ℃ can completely eliminate this effect.

3 Conclusion During the casting and rolling process of 4343 aluminum plate, the structure of different positions on the same plate surface is very different. The upper and lower parts of the cast-rolled slab are well organized, and the eutectic silicon aggregates in a lath-like distribution, and there is a risk of fracture. A large amount of eutectic silicon and Fe, Mn and other elements form Fe Si Al

- Al Mn Fe Si and other compounds, which gather in the middle of the 4343 aluminum plate cast-rolled slab, will have an adverse effect on the structure. After homogenization annealing, the alloying elements are fully diffused and the as-cast structure is improved. The results show that annealing at 520 ℃ is beneficial to reduce the risk of fracture.