The brazing of steel and aluminum is very poor, not only the melting point of the two is very different: the melting point of steel is about 1350℃, the melting point of aluminum is about 660℃; the density difference is also very large: about 7.87t/m3 for steel and 2.70t/m3 for aluminum....

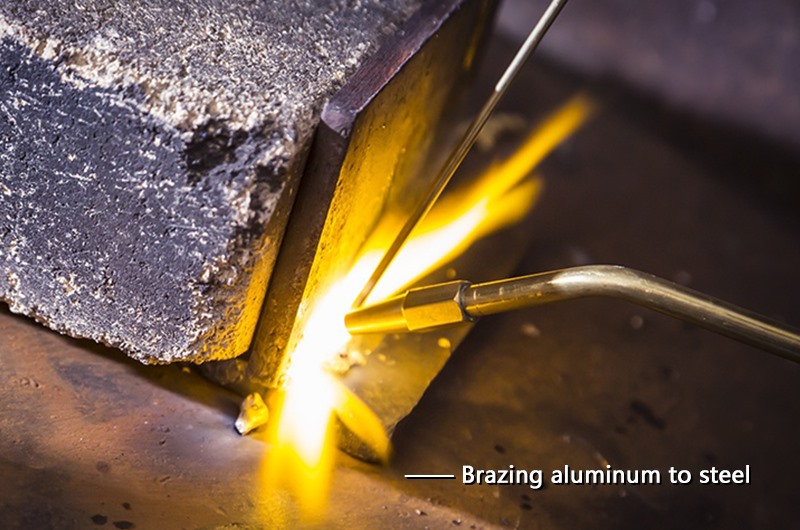

Introduction of brazing aluminum to steel

The brazing of steel and aluminum is very poor, not only the melting point of the two is very different: the melting point of steel is about 1350℃, the melting point of aluminum is about 660℃; the density difference is also very large: about 7.87t/m3 for steel and 2.70t/m3 for aluminum. In addition, a refractory oxide film is easily formed on the surface of aluminum to hinder the combination of the two. The gas welding process of steel and aluminum is essentially "brazing-fusion welding", that is, brazing on the steel side and fusion welding on the aluminum side. Controlling the temperature during gas welding can avoid brittle structures and obtain good joints.

Method of brazing aluminum to steel

Gas welding of steel and aluminum:due to the difficulty of direct gas welding of steel, the method of first hanging silver on the steel, that is, using a transition layer, and then welding with aluminum. The specific welding process is as follows:

①Cleaning up before brazing, first use acetone, alcohol or gasoline to remove oil stains on the weldment, and then carry out chemical cleaning. Immerse the welded part of stainless steel in an aqueous solution of 30% nitric acid, 3% sodium chloride, and 3% sodium fluoride, take it out after 0.5 to 1 hour, and then immerse it in an aqueous solution of 40% nitric acid and 10% potassium dichromate, and passivate it for 0.5 to 1 hour. 1h, take out, wash with water and dry. Immerse the welding part of the aluminum parts and the welding wire in a 15% sodium hydroxide solution, and after 5 to 10 minutes, make the sodium hydroxide react with alumina to generate easily soluble aluminum hydroxide, take it out, and wash it with water. Then immerse it in 20% nitric acid aqueous solution, carry out neutralization reaction for 2 to 3 minutes, take out and wash with water and dry.

②Brazing process, using slight carbonization flame as welding flame. Heat the welding part of the stainless steel part to about 300℃, and then heat the end of the material HL303 (silver brazing filler metal) to the same temperature, dip it in the flux 102, apply it to the welding part, and continue to heat the welding part to 600~700℃ , and fill with HL303, the thickness of the layer to be welded reaches 0.3mm, and the temperature of the weldment is 500 to 600℃, put the aluminum part into the place to be welded, and use a neutral flame to heat the aluminum part and the end of the wire 301 to 300 to 400℃, Use wire 301 dipped in gas agent 401 for welding.

During operation, it is necessary to pay attention to the uniform movement of the welding wire, to fill the molten pool, to keep the metal in the molten pool from being oxidized, to remove the gas, oxides and other impurities in the molten pool, and to avoid pores and cracks in the weld. Welding should be carried out continuously, preferably at one time, and rapid welding should be used as much as possible.

③Clean up after brazing, carefully wash the joints with a stiff brush in hot water, and then immerse them in a chromic anhydride aqueous solution or potassium dichromate solution with a concentration of 2% to 3% at a temperature of 80℃ for about 3 to 5 minutes. Carefully scrub with a stiff brush, rinse in hot water, and dry.