Low temperature aluminum brazing wires ER4047/ER4043 can weld white metal, including aluminum, aluminum alloy, cast aluminum, aluminum-magnesium alloy and dissimilar welding between the above metals, even for white metal that has been severely rusted or oily, suitable for primary welding operations to all-round welding, only a small heating device is required...

Introduction of low temperature aluminum brazing wires ER4047/ER4043

Low temperature aluminum brazing wires ER4047/ER4043 can weld white metal, including aluminum, aluminum alloy, cast aluminum, aluminum-magnesium alloy and dissimilar welding between the above metals, even for white metal that has been severely rusted or oily, suitable for primary welding operations to all-round welding, only a small heating device is required. The strength of the weld after welding is generally higher than the strength of the base metal itself, and it is enough to understand the gas welding operation.

The melting point of pure aluminum is 660.37 degrees Celsius, while the melting point of aluminum alloy is 482-660 degrees Celsius depending on the alloying elements it contains. When aluminum and aluminum alloys are heated from room temperature to a molten state, there is no color change. It is very difficult to judge the temperature of the base metal during welding, and it is easy to overburn or melt the base metal.

The temperature definition of low temperature aluminum welding wire is mainly based on three temperature ranges:

- Low temperature aluminum welding wire at 580-620 degrees Celsius. Representative welding wire ER4047, ER4043

- Low temperature aluminum welding wire at 380-450 degrees Celsius. Represents welding wire Q303, WE-Q303B, WE53, etc.

- Low temperature aluminum welding wire at 179 degrees Celsius. Represents welding wire M51, M51-F.

ER4043 low temperature aluminum silicon brazing rod wire

Standard: GB/T10858 SAI4043 AWS A5.1 ER4043

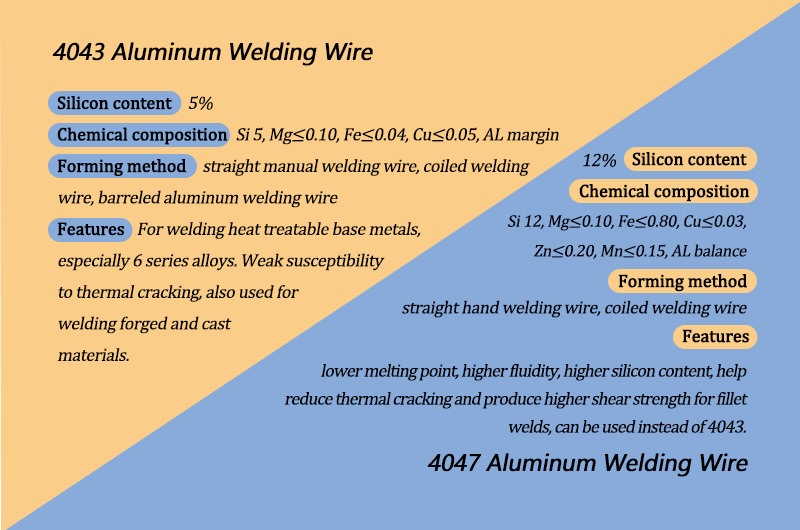

Composition: Si=4.5-6.0%; Fe≤0.8%; Al balance.

ER4043 is an aluminum-silicon alloy welding wire containing 5% silicon, with a melting point of 573-625 °C, good fluidity, strong thermal crack resistance, but insufficient ductility. Due to the high silicon content, when used for welding high magnesium alloys, brittle Mg2Si is easily formed in the weld, which reduces the plasticity and corrosion resistance of the joint. In addition, the color of the weld surface is dark, and the color of the base metal is different after anodization.

Uses: Used as filler material for argon arc welding and gas welding of aluminum alloy workpieces and castings other than aluminum magnesium alloys. Commonly used for welding of 600 series aluminum alloys such as 6061, 3000 series and 2000 series aluminum alloys and cast aluminum. Widely used in railway locomotive chemical food and other industries.

ER4047 low temperature aluminum silicon brazing rod wire

Standard: GB/T13815 BA188Si AWS A5.1 ER4047

ER4047 silicon alloy aluminum welding wire, which has a lower melting point of about 500 ℃ and higher fluidity than ER4043 (silicon content of 12%) can also be used as a welding material. Can be used in place of ER4043, with higher silicon content to help reduce thermal cracking and produce higher fillet weld shear strength.

Application: Commonly used for various difficult welding of aluminum (thin) parts, condenser air-conditioning pipes, high-pressure aluminum pipes, automobile water tanks, fuel tanks, etc.