Aluminum brazing refers to a welding method in which the solder and the solder that are lower than the melting point of the solder are heated to the melting temperature of the solder at the same time, and then the liquid solder is used to fill the gap of the solid workpiece to connect the metals....

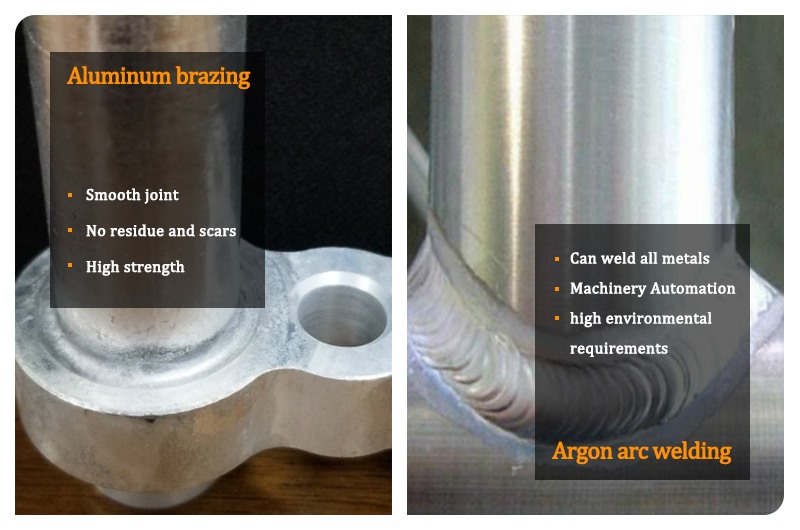

Aluminum brazing refers to a welding method in which the solder and the solder that are lower than the melting point of the solder are heated to the melting temperature of the solder at the same time, and then the liquid solder is used to fill the gap of the solid workpiece to connect the metals. During brazing, the oxide film and oil stains on the contact surface of the base metal should be removed first, so that the capillary can play a role after the brazing filler metal is melted and increase the wettability and capillary fluidity of the brazing filler metal. The advantages of brazing are obvious. The surface of the joint is smooth and beautiful, without any residues and scars. The strength of the workpiece after brazing is also greater than that of argon arc welding, and the environmental requirements are not so harsh.

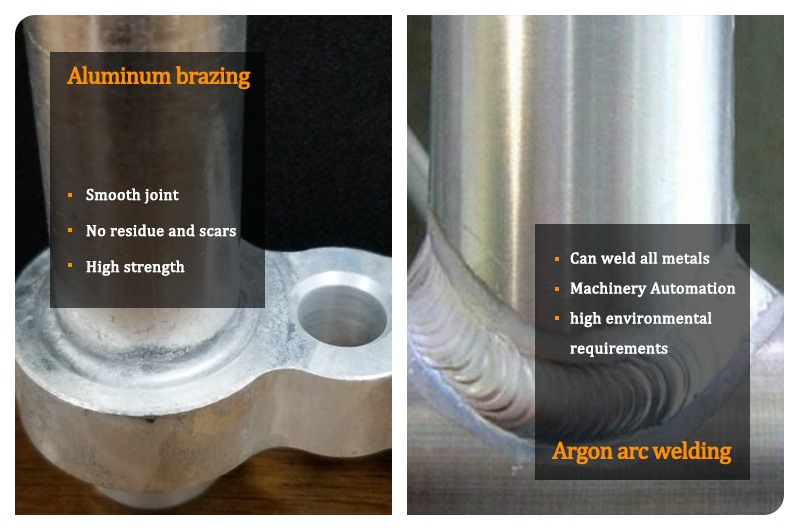

Argon arc welding has been used all over the world for decades, and the maturity of the technology has almost reached the top. The advantages of argon arc welding are obvious: almost all metals can be welded, and it is relatively easy to mechanize and automate. However, the disadvantages are also obvious: strong arc light and flue gas are generated during the argon arc welding process, so the work protection of the welder and the ventilation of the surrounding environment are relatively high. Another point is that in recent years, the requirements of each industry on the appearance of products have become more and more strict. Compared with brazing, the appearance of argon arc welding does not seem to have an advantage.